KITS

DENVELOPS Comfort

The Denvelops Comfort represents a highly versatile, adaptable, and scalable off-site prefabricated Plug-and-Use solution. It comprises vertical stainless-steel support structures and connectors that enable seamless attachment and load-bearing capabilities for the cladding. The thermal insulation utilizes mineral wool and is protected by a protective weathering layer, both affixed to the vertical support structures to ensure optimal thermal performance and waterproofing. Additionally, the mineral wool is shielded by a layer of glass fibre, providing mechanical damage protection. Notably, this system incorporates a minimum of 50% recycled materials. The facade cladding is crafted from painted aluminium tiles with a durable powder coating. Furthermore, PV panels have been seamlessly integrated into the facade, effectively replacing the conventional cladding materials.

At the heart of Denvelops Comfort lies a pioneering HVAC component: the Air Handling Unit, ingeniously crafted in collaboration with CVUT. Positioned vertically, this unit boasts a dualstage heat recovery system. The first stage employs a plate heat exchanger, while the second employs an active heat exchanger equipped with thermoelectric modules to regulate the supplyair temperature. This unit is seamlessly connected to the interior space through supply and extract channels, ensuring precise climate control.

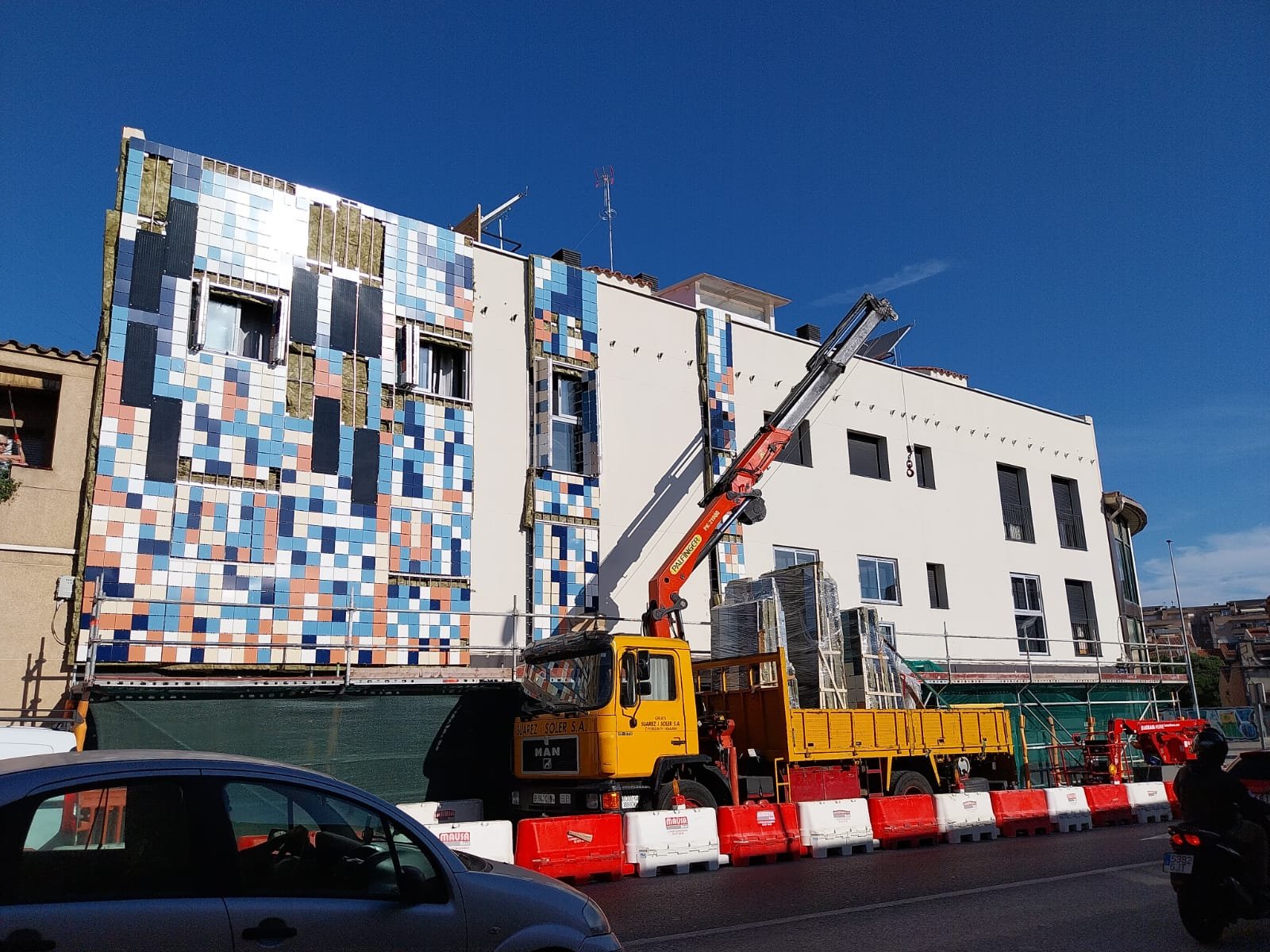

Demonstrated in Terrassa, Spain

BEFORE

DURING

ConExWall

Manufacturing and Assembly

Installation

The ConExWall (eWHC) is a specifically designed smart solution to be used in colder climates, such as continental and alpine locations. What makes it special? It's built with timber, chosen for its eco-friendliness and flexibility in shape and size. It's a dynamic heating and cooling system.

Imagine your wall being a part of your heating setup. The ConExWall can do just that. It's designed to store heat, which means when you have extra electricity from solar panels, you can heat your space longer and hotter. And when you need to buy electricity, it helps you use less.

It's like having a built-in energy saver. But that's not all, it's also smart. With sensors and controls, it monitors the weather, temperature, and air quality to keep your space just right. And underneath its sturdy timber exterior lies layers of insulation, making sure it fits against your wall, no matter its shape or size.

Demo site Kašava, Czech Republic

ConExWall isn't just a wall – it's a sustainable, adaptable, and smart way to keep your space comfortable in cold climates!

The Kašava demo site, situated in the Zlín region of the Czech Republic and owned by the Municipality of Kašava, is undergoing a transformation led by Pich Architects. Originally built in the 1950s as part of an elementary school, the multifamily house – headmaster's residence, nestled into a southern slope. The two-story structure, with a basement, had a smaller usable space on the second floor due to its roof design. While the room orientation is advantageous, the layout no longer meets modern family living standards. Constructed traditionally with bricks and reinforced concrete ceilings, the house relied on a coal boiler for heating until the late 1990s, when it was updated with electric boilers. Today, the building serves as housing, accommodating two apartments for teachers from a nearby nursery school.

The primary goal of the renovation is to enhance energy efficiency and user comfort by upgrading the entire thermal envelope of the building. This involves using PnU kits to insulate external walls and modified prefabricated elements for new roof structures. Recognizing that the existing roof shape didn't optimize space or allow for easy PnU kit application, the design team decided to change the roof's configuration.

In addition to insulation, ventilation units with heat recovery are integrated to enhance air quality and user comfort. Furthermore, renewable energy sources like photovoltaic panels and a heat pump are being installed to decrease primary energy consumption. These measures aim to modernize the Kašava demo site while making it more sustainable and comfortable for its occupants.

-

Before installing the ConExWall system, several preparatory steps are required. These involve preparing the current walls by fixing any defects, ensuring flatness, and making space for the anchoring system. Additionally, holes for pipes and cables will be created as per the production plan.

-

The installation process begins with setting up an anchoring system for the ConExWall panels on the outer walls. Panels are then installed on the first floor, adjusted to fit heat transfer layers, and cables are routed through prepared openings.

This process is repeated for the second floor and completed with roof panel installation. All connections and testing of technologies are performed during this phase.

-

If roofing, photovoltaic (PV), and facade cladding are not assembled initially, they will be installed on-site after panel installation to avoid damage during transport.

-

Utility installations such as ventilation units, heat pumps, and electrical systems are installed at this stage. Interior renovations are also carried out as necessary.

-

A control system is installed and tested, including the heating, DHW, AHU, and PV systems, as well as plumbing pressure tests.

-

The entire system undergoes final testing and commissioning before being connected to the grid.

The ConExWall is made by a Czech company called RD Rymarov (RDR). They use advanced machines to make most of the panels, like bridges and tables that move automatically. They also use forklifts or cranes to move materials around. Workers mainly handle wood and put together the frames, add insulation, and install special parts like heating layers.

Making ConExWall involves five stages:

-

Making the frame of the ConExWall. The materials are moved from storage to shaping centres, the timber is cut and prepared. Large materials (boards) are cut into the right sizes and the wall panels are assembled. The same is done for the roof and ceiling panels.

-

Installation of components like heaters, windows, doors, ventilation systems, wiring and cable protection pipes.

-

Insulation installation to the walls and ceilings.

-

Electrical and mechanical components like heaters and ventilation units are installed on the wall panels.

-

Finishing touches like adding wooden cladding to the walls if it wasn't done already and the completed panels are moved to a pickup area in the expedition hall.

Results of ConExWall

We can save a lot of time and money in construction by using modern technology and smart planning. Initially, we use things like 3D scanning to carefully map out the building's current condition, which helps us plan better.

Then, we cut down even more time and costs by making parts of the building in a factory instead of on-site. This off-site construction means we're not at the mercy of bad weather, and we can use machines to work faster and more efficiently. We also save on materials and packaging because we transport pre-made panels directly to the site. Overall, this method allows us to finish installing everything in just about a week, with the help of a crane.

SmartWall is a multifunctional wall system that combines active with passive technologies, including fully prefabricated walls, high-performance windows, balcony doors, slim-type fan coil for heating and cooling, split units, air ducting systems, radiators and convectors, PV panels, batteries, control and fire protection systems. It is a compact versatile prefabricated kit which can be installed externally or internally (in case there are space or aesthetic restrictions) in existing building envelopes, introducing an innovative, dynamic, and flexible retrofitting solution reducing installation time and construction faults. The SmartWall systems are easily adjustable to any dimension up to 4m of height per module and can be decorated with any kind of finishing material. SmartWall systems are suitable for almost all building types and climatic conditions, while it is more effective for climates with significant cooling demand. Furthermore, some but not limited, technological devices that could be incorporated (prefabricated in order to reduce actual installation time) within the SmartWall systems, are:

· Fan coils

· Air condition/split units

· Air ducting systems

· Radiators

· Heat panels

· Solar panels

SmartWall

It has to be noted that almost 98% of the materials used for SmartWall production are recyclable and eco-friendly and only the air purification filters of the ventilation system cannot be recycled.

A comprehensive description of SmartWall Systems capabilities, technological devices and SmartWall modular combinations have been extensively presented in Deliverable – Technologies and Material selected for demo sites.

Demonstrated in Voula, Greece

Voula renovation started on 20.03.2023 and was completed on 31.07.2023, corresponding to 96 calendar days in total, divided into three phases:

a. Phase 1: Auxiliary works for SmartWall installation, including PV’s, ETICS, electrical wiring, and HVAC systems installation including their pipework: 20.03.2023 – 09.05.2023 with the actual duration of forty (40) working days.

b. Phase 2: Preliminary works for SmartWall installation, e.g. removal of balconies’ doors, local repairs of the existing brickwork, modifications on SmartWall panels and supporting metal frames production due to the extensive damages revealed in the brickwork after balconies’ doors removal, etc.: 20.05.2023 – 20.07.2023. Its actual duration was forty-one (41) working days.

a. Phase 3: the actual SmartWall installation: 08.06.2023 until the project’s completion on 31.07.2023 with an actual duration of thirty-eight (38) working days.

BEFORE

AFTER

Environmental Assessment of PnU kits

The products that are analysed in this project:

The SmartWall is an industrialized panel implemented at the Greek demo site. The analysed unit includes a window and a fan-coil unit.

Denvelops Comfort is an industrialized panel implemented at the Spanish demo site. The analysed Unit includes a window and an Air Handling Unit.

The ConExWall/eWHC is an industrialized panel implemented at the Czech demo site. The analysed unit includes windows.

General Information on the Object of Assessment

Greek Demo Site - VVV– SmartWall

Functional equivalent: PnU kit SmartWall located in the Greek pilot demo-site in Voula-Athens

Building type: Block of residential dwellings, Self-standing in urban environment

Relevant technical and functional requirements: Greek Building regulation, “Regulation on the Energy Performance of Buildings – KENAK”

Usage profile: A shelter for homeless or low-waged families

Reference study period: 50 years

General Building Information

The building was constructed in 1971 in two stages; initially the basement, the ground floor, and the first floor (Initial Building Permit), and in a second stage, the second floor was added (Supplementary Building Permit).

Year of commissioning: 1971, 2020 started the PLURAL renovation

HVAC and DHW systems: Fan coil, DHW via solar collectors

Energy systems: PV panels, solar collectors, heat pumps, Battery (SmartWall)

Spanish Demo Site – Terrassa - DENVELOPS Comfort

Functional equivalent: PnU DENVELOPS Comfort kit placed in the Spanish pilot building in Terrassa

Building type: Block of residential dwellings

Relevant technical and functional requirements: Basic Document HE Energy savings. HE1. Conditions for energy demand control

Usage profile: Multifamily residential block in an urban environment

Reference study period: 50 years

General Building Information

Year of commissioning: 2006

HVAC and DHW systems: Ventilation unit for Denvelops HybridWall, electric radiators, DHW via solar collectors

Energy systems: PV panels, solar collectors

Czech Republic Demo Site - Kasava - ConExWall

Functional equivalent: PnU ConExWall kit placed in the Czech pilot building in Kasava

Building type: Multiple - double dwelling house

Relevant technical and functional requirements: N/A

Usage profile: A double residential house located in a natural environment

Reference study period: 50 years

General Building Information

The construction system of the building is the longitudinal walls. The walls are made of burnt bricks. The roof structure is hipped with two dormers. The supporting structure of the roof is a purlin system with wooden elements - rafters. The sheet metal is used as roofing.

Year of commissioning: 1962

HVAC and DHW systems: ConExWall concept, Facade panels with air handling and heating/cooling system

Energy systems: Integration of BIPV system and/or solar thermal for DHW, air-to-water heat pump

Assessment of PLURAL Demo Sites

The analysis of the design and assessment of the PLURAL demo sites considered key aspects of thermal comfort, indoor air quality, and acoustics, with specific reference to international and regional regulations. While measures are applied to exceed minimum requirements in several indicators, some areas, such as air velocity and specific acoustics, lack sufficient information for assessment. Comfort and air quality management is mainly carried out at zone level, with manual or automatic control options, ensuring an efficient and comfortable living environment.

Environmental Assessment

Environmental assessment of the PLURAL "Plug-and-Use" kits, focusing on Life Cycle Assessment (LCA), Life Cycle Costing (LCC), and Social Assessment.

LCA findings

LCC findings

Social assessment (only the indicators that apply to the PnU kits)

The main LCA conclusion is that the phase where most of the highest impacts occur is in the product phase. This phase includes material extraction, manufacturing of various products and their assembly to the final component (prefab PnU kit), including transportation as well. This can be justified, considering that the PnU kits are prefabricated elements, where all products/layers of the components are gathered in the factory, where also the assembly to the final configuration takes place. On the other hand, it can be observed that the construction and maintenance phases have almost no relevant impact. Energy consumption, water resources and other environmental factors are greatly reduced. This may be attributed to the fact that the construction phase has minor use of machinery and therefore energy consumption because the elements are prefabricated. Regarding the maintenance phase, prefabricated façades do not require a significant use of resources. Configurations that incorporate a fan coil and the ventilation unit, whose maintenance and replacement are required every 15 years, present higher environmental impacts. Finally, in the deconstruction phase, as the PnU kits are prefabricated and assembled façades, their separate elements can be reused at the end of their lifetime avoiding waste.

In summary, with this assessment, it can be verified that the general impact of all configurations is less than that of a conventional system and that, especially in the construction phase, the impact is reduced.

The utilization of the social assessment has been extended to encompass the PLURAL PnU kits, specifically the SmartWall, ConExWall, and DENVELOPS COMFORT. Consequently, the scope of the assessment scenario, encompassing the object of evaluation, building model, and functional equivalent, is confined to the specifications of these kits. Consequently, indicators pertinent to other facets of the building are excluded from the assessment.

The evaluated indicators have been designed according to European and national standards of Greece, the Czech Republic and Spain and they comply with social performance assessment parameters as described in EU standard EN 16309.

The formulated indicators under evaluation adhere to the European and national standards of Greece, the Czech Republic, and Spain. Additionally, these indicators align with the social performance assessment parameters delineated in the EU standard EN 16309. In summary, the design, manufacturing, and application of the PLURAL PnU kits to their respective demonstration sites conform to and satisfy the social performance assessment criteria.

Finally, a digital model is introduced, which provides in depth assessment regarding the LCA and LCC and Social performance of the PLURAL PnU kits. An analysis has been made of how the information of the current digital models (structured in ifc format) hinder the exploitation of the data and related limitations. As a result, a new structure model is proposed.